Q: What types of glass do you use the most?

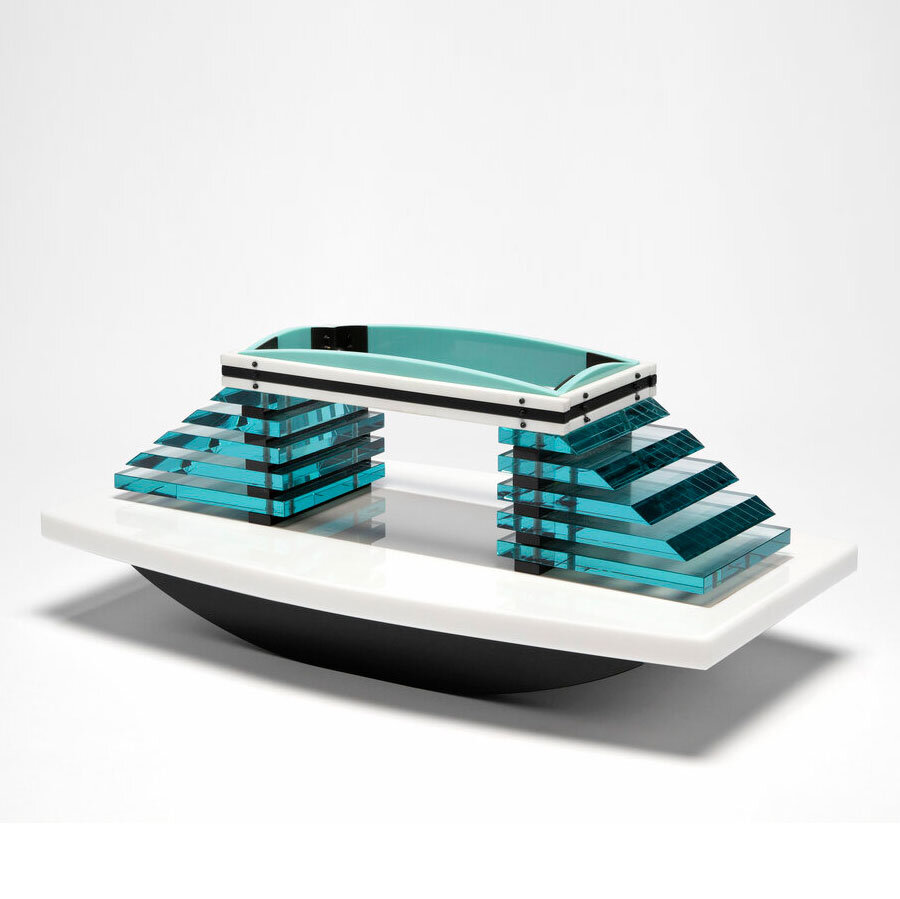

MACNEIL: PLATE GLASS. Plate glass is the type of medium I use the most because as an artist I like to be in control of both form and color and because the forms I make are precise. I use both vintage and contemporary plate glass. Today’s industrial plate glass has great clarity and comes in reliable measurements and vintage plate glass comes in different thicknesses and in unusual, opaque colors, both are great for use in my designs. I use them in combination with each other as well as independently.

“Vitrolite” is a brand name for a vintage plate glass manufactured at scale between 1920-50. All colors are opaque. The Vitrolite color palette ranges from rich deco era black, cream, reds, greens, blues to a variety pastel colors and white.

Vitrolite was a material mostly used for surfaces like exterior and interior walls, tiles and countertops as an alternative to what had been used before (wood, marble and ceramic). It became ubiquitous during the Art Deco (and Art Moderne) period and was key component of the architectural aesthetic. My husband Dan and I have been collectors of Vitrolite and vintage glass since the 70s. See an example of Vitrolite in his work below.

Today’s industrial plate glass for architectural applications is manufactured by a “floating” process and is called float glass. The thickness ranges generally from 1/8-1 inch. The typical plate glass is transparent / clear and is available in many tints. Its clarity is mostly perfect to the eye and readily available for purchase.

Bending and shaping plate glass

Plate glass can be bent with controlled heat in a kiln environment. This technique is called “slumping” and I use it often.

“Popular among glass artists today, as it was in the golden age of Greece and the Roman Empire, this technique softens and shapes glass in a kiln. “ – Corning Museum of Glass.

VINTAGE GLASS AND HISTORY OF VITROLITE

From an article titled “Vitrolite Finds Itself Once Again in Demand” by MONICA WATROUS / McCLATCHY NEWSPAPERS

published on The Ledger in 2007 and “What is Vitrolite? Another Question Answered by the Hagley Library” January 20, 2014

1900: Marietta Manufacturing Co. of Indianapolis produces its first sheet of “substitute for marble” called Sani-Onyx

1906: Penn-American Plate Glass Co. of Pittsburgh manufactures white and black Carrara glass

1908-1935 The vitreous marble product called Vitrolite was produced by The Vitrolite Company

1913: The first large-scale interior application is completed in the restrooms of New York’s Woolworth Building

1920s: Art Deco movement begins; architects begin substituting structural pigmented glass for traditional materials in projects

1930s: More exotic colors become available, including tropic green, forest green, robin blue and jade; glass veneers become synonymous with the “modern look,” as many downtowns update with the material

1935-1947 Libbey-Owens-Ford Glass of Toledo, Ohio, takes over producing Vitrolite

1939: Art Deco period ends; World War II begins

1947: Manufacturers stop producing structural pigmented glass

Learn more about STUCTURAL PIGMENTED GLASS here (on Wikipedia)

This post is drawn from a “Conversation with Katja” that began in 2021.